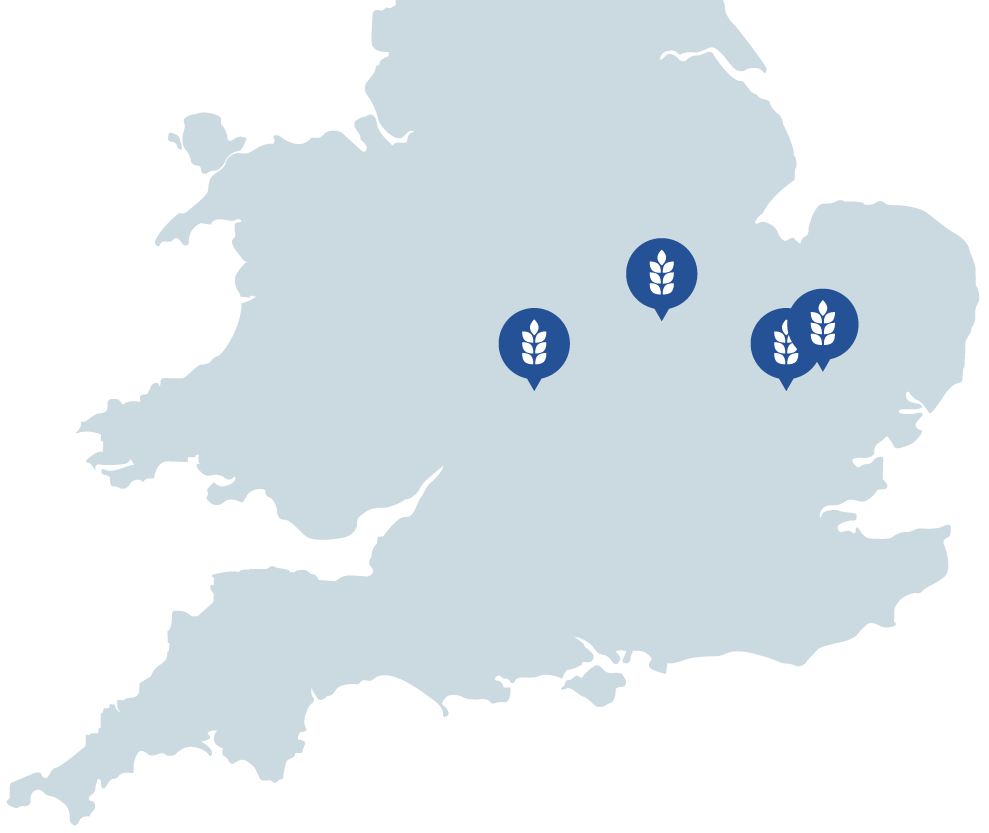

Storage Locations

Camgrain Operations

- Camgrain operates three sites working as one co-ordinated unit to optimise farmer collections and customer deliveries.

- Camgrain also has exclusive use of storage at RCMA Agri's site at Stratford-Upon-Avon.

- The locations of these sites offer farmers and customers major efficiency gains throughout the marketing year.

- Members' crops are delivered to the site closest to the end market, capturing the initial move into central store at harvest as part of the journey process to the customer, saving transport cost and food miles.

- Members of Camgrain are not members of a particular store, their grain will simply leave the farm and go to the most appropriate site for the crop.

Cambridge

Cambridge is our biggest store and specialises in storing and handling premium wheats. It has one of the largest colour sorting plants in the country able to clean and sort grain at over 100t per hour along with four continuous flow grain dryers that are able to dry up to 180t per hour.

Our Cambridge site is also home to our Clean Wheat Plant, the first in the farmer owned central storage market to gain BRCGS grade AA accreditation, a key differentiator in the supply chain and a route to providing new added value markets for members. Operating a state-of-the-art Clean Wheat Plant, the store has opened up access into the breakfast cereal market for Camgrain members, bringing added value to Group 3 and Group 4 wheats. Capturing grant aid has helped build a store that is highly energy efficient, bringing the direct benefits of scale into drying operations and construction.

Linton

Linton was the first site to be developed as part of the Camgrain storage co-operative. In 1983 it was a green field site, storing 10,000 tonnes of members’ produce in the first year of operation. With continuous investment and maintenance, the site has grown into one of the most progressive grain handling plants in the UK. At Linton, we specialise in all niche sector crops and the store is OF&G (organic) accredited. We have the ability to segregate and blend a wide variety of crop types and variety quality bands.

Malting barley is the major crop stored at this site, reflecting the stores proximity to the malting barley growers and East Anglian malting barley industry. Spread across fifteen acres, the site stores over 150,000 tonnes annually and has intake capacity for up to 10,000 tonnes per day. It also has a high-speed colour sorter to deal with any quality issues that arise.

Northants

Located between Kettering and Corby, the Northants site is strategically located at the centre of England, near major arterial roads and close to many onward consumers of farm grain. This makes it an ideal location for storing crops for onward distribution, reducing food miles and carbon footprints.

In 2024, Navara Oat Milling opened alongside our grain store providing an ideal onward customer on our doorstep and helping Camgrain to maximise the value of our members' oats. At Northants we have both extensive drying and cleaning equipment making it suitable for the storage of high-quality Group 1 Milling Wheat.

Stratford

At Stratford we store a wide range of crops and, like Linton, it is OF&G (organic) accredited. Stratford also has the added advantage of storing OSR alongside the Yelo Oilseed Rape crush plant reducing food miles and supply chain costs. An additional benefit of storing crops at Stratford is that it provides access to a variety of feed markets in the west of the country.

While Stratford is no longer 'owned and operated’ by Camgrain, we have secured a services agreement allowing continued use of the storage by our members adding value while reducing our cost burden.